Common menu bar links

Canola: a Canadian success story

Archived Content

Information identified as archived is provided for reference, research or recordkeeping purposes. It is not subject to the Government of Canada Web Standards and has not been altered or updated since it was archived. Please "contact us" to request a format other than those available.

by Luc Casséus, Statistics Canada

With its vibrant yellow flowers, a canola field is a beautiful sight. And its colour is a clue to its family history—mustard.

With its vibrant yellow flowers, a canola field is a beautiful sight. And its colour is a clue to its family history—mustard.

“Canola” refers to a particular group of rapeseed varieties, a species of the much larger mustard family that includes, besides mustard, turnips, cauliflower, cabbage and broccoli. While these plants have been bred for their roots (turnips), leaves (cabbage) or immature flower heads (cauliflower and broccoli), the rapeseed branch of the family was bred to maximize production of the high-oil seeds that are used to produce vegetable oil.

An ancient oilseed, rapeseed was cultivated in Asia and Europe as a source of lamp oil and, later, cooking oil. Much later, its physical properties made it an essential lubricant for steam engines on naval and merchant ships.

It was first grown in Canada as an emergency measure during the Second World War when European and Asian supplies were cut off. Canada responded by quickly increasing its limited rapeseed production. But by 1950 steam power had been converted to diesel and the crop almost disappeared.

Until the 1960s Canada’s edible oil production was based on imported oilseeds, a market opportunity that researchers quickly identified as a potential saviour for the flagging rapeseed sector. The main impediment to edible oilseed production was the significant levels of erucic acid and eicosenoic acids, both nutritionally undesirable. Rapeseed also contains sulphur compounds called glucosinolates, which at low levels impart the sharp flavour characteristic of certain vegetables such as radishes and mustard but which, at high concentrations, limit the usefulness of rapeseed for consumption by humans and livestock.

The solution was canola (an abbreviation of “Canadian oil”), developed by plant breeders in Saskatchewan and Manitoba during the 1960s and 1970s. Through traditional cross-breeding experiments, they minimized the undesirable compounds and developed varieties that yielded food-grade oil. By the 1980s, canola had replaced rapeseed in Canadian oilseed production.

The solution was canola (an abbreviation of “Canadian oil”), developed by plant breeders in Saskatchewan and Manitoba during the 1960s and 1970s. Through traditional cross-breeding experiments, they minimized the undesirable compounds and developed varieties that yielded food-grade oil. By the 1980s, canola had replaced rapeseed in Canadian oilseed production.

The small yellow flowers characteristic of the canola plant produce tiny round seeds in small pods. These seeds are crushed to produce oil, and the remainder is processed into meal, which can be used as a high-protein livestock feed.

What’s in a name?

Canola is a term trademarked and licensed by the Canadian Canola Council to differentiate the plant, oil and meal from traditional rapeseed. The strict definition is that canola oil must have less than 2% erucic acid and the seed must contain less than 30 µmol of glucosinolates per gram of air-dried oil-free meal. In some countries the term “double-zero rapeseed” (referring to low acid and low glucosinolate) or “canola-quality” are used to describe these newer varieties of seed, oil and meal, while other regions continue to refer to both the old and new varieties as rape or rapeseed.

Canola/rapeseed crop area in Canada

Since the Census of Agriculture first began tracking the crop in 1956, the area planted to rapeseed and later canola has expanded steadily, from 143,000 hectares to 5.0 million hectares in 2006. Canola production in Canada is still overwhelmingly concentrated in the Prairies (Saskatchewan, Alberta, Manitoba and the Peace River region of British Columbia), which account for 99% of total seeded area (Table 1 and Map 1). However, canola is also seeded in all other provinces except Newfoundland and Labrador.

Since the Census of Agriculture first began tracking the crop in 1956, the area planted to rapeseed and later canola has expanded steadily, from 143,000 hectares to 5.0 million hectares in 2006. Canola production in Canada is still overwhelmingly concentrated in the Prairies (Saskatchewan, Alberta, Manitoba and the Peace River region of British Columbia), which account for 99% of total seeded area (Table 1 and Map 1). However, canola is also seeded in all other provinces except Newfoundland and Labrador.

Canola/rapeseed production

The 5.0 million hectares of canola planted in the 2006 crop year yielded approximately 9 million tonnes of canola. After peaking at 9.5 million tonnes of canola in 2005, 2006 production was still well above the previous five-year average of 6.7 million tonnes. Since 2006, production has been on the rise, and by 2008 surpassed 10 million tonnes.

Over half the 9 million tonnes of canola produced in Canada was exported in 2006 (Table 2). In 2006, Canadian rapeseed production ranked second in the world behind China and ahead of India, Germany and France (Table 3). (The broader category of rapeseed is used to compare canola production and trade data with other countries.)

Increasing yields, marketing higher-quality crops and increases in both canola prices and quantity sold have helped boost Canada’s farm cash receipts for canola. By 2005 the crop had surpassed wheat to become the most valuable field crop in Canada.

Increasing yields, marketing higher-quality crops and increases in both canola prices and quantity sold have helped boost Canada’s farm cash receipts for canola. By 2005 the crop had surpassed wheat to become the most valuable field crop in Canada.

In 1976, canola accounted for only 4.9% of total crop receipts; by 2006, this percentage had climbed to 17.2%. Over the same period, wheat receipts dropped from 35.5% to 15.0% of total crop receipts. Farm cash receipts for wheat totalled $2.2 billion in 2006, while those for canola totalled $2.5 billion.

Canola is often grown in rotation with Canada’s traditional cereal crops of wheat, oats, and barley. The area seeded with canola varies according to prevailing economics among other factors, but the trend is to increasing area. Wheat, on the other hand, has been showing the opposite trend in planted area (Figure 1). However, between 2006 and 2008, the planted area for both crops has increased, wheat by 4% and canola by 21%.

Figure 1

Wheat and canola/rapeseed seeded area, census years 1961 to 2006

From seeds to oil

Raw canola is converted to oil for use in most consumer products through a process called “crushing.” (For more on this process, see “How to crush canola.”) Ten crushing facilities currently operate in Canada, mainly in the Prairies, and a number of new plants are under construction. Still others are undergoing expansion. In 2006, total canola crushing reached 3.6 million tonnes of seed, well above the 2.9 million tonnes averaged in the previous five years.

Raw canola is converted to oil for use in most consumer products through a process called “crushing.” (For more on this process, see “How to crush canola.”) Ten crushing facilities currently operate in Canada, mainly in the Prairies, and a number of new plants are under construction. Still others are undergoing expansion. In 2006, total canola crushing reached 3.6 million tonnes of seed, well above the 2.9 million tonnes averaged in the previous five years.

All of this crushing makes Canada the world’s fourth-largest producer of canola/rapeseed oil, with 1.6 million tonnes of oil in 2006 (Table 4).

Canada is the world’s largest exporter—approximately 84% of the oil produced in 2006 was exported, representing over half of the world’s total canola/rapeseed oil exports. More than half of our exported canola oil went to the United States. Table 5 shows other major destinations.

A popular choice

In 2006, approximately half of all oil consumed by Canadians was canola. Its low cost, high smoke point and reputed nutritional benefits make canola oil a popular choice. Canola oil has a smaller proportion of saturated fatty acids than any other vegetable oil, and consists mainly of monounsaturated and polyunsaturated fatty acids (Table 6).

In October 2006, the U.S. Food and Drug Administration (FDA) authorized the use of a health claim for canola oil that states:

In October 2006, the U.S. Food and Drug Administration (FDA) authorized the use of a health claim for canola oil that states:

Limited and not conclusive scientific evidence suggests that eating about 1½ tablespoons (19 grams) of canola oil daily may reduce the risk of coronary heart disease due to the unsaturated fat content in canola oil. To achieve this possible benefit, canola oil is to replace a similar amount of saturated fat and not increase the total number of calories you eat in a day.

The 2007 Canada’s Food Guide recommends choosing unsaturated fats and lists canola among the recommended vegetable oils.

Other canola products

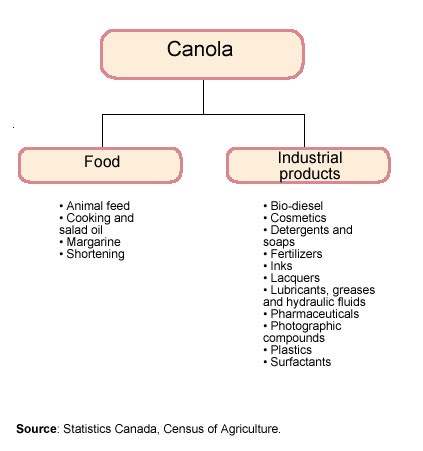

While canola is obviously important for oil production, it is also the source of a number of other valuable products (Figure 2). Canola meal (what’s left of the canola seeds after the oil has been extracted) is a rich source of vitamins B and E and is a protein source for the aquaculture and animal feed industries.

Current demand for canola meal is strong given the tight world protein supply for animal feed. In fact, canola and rapeseed meals are the second most widely traded protein ingredients in animal feed after soybean meal. Almost all the demand for Canadian canola meal is from the U.S. dairy industry. The United States imported approximately 98% of Canada’s 1.5 million tonnes of exported canola meal in 2006. As production of canola increases and more meal is available, it may become more widely used by other livestock sectors such as the poultry and hog industries.

Current demand for canola meal is strong given the tight world protein supply for animal feed. In fact, canola and rapeseed meals are the second most widely traded protein ingredients in animal feed after soybean meal. Almost all the demand for Canadian canola meal is from the U.S. dairy industry. The United States imported approximately 98% of Canada’s 1.5 million tonnes of exported canola meal in 2006. As production of canola increases and more meal is available, it may become more widely used by other livestock sectors such as the poultry and hog industries.

Figure 2

The many uses of canola

A crop that never stops improving

The rapeseed industry in Canada started with demand for an industrial lubricant and recent research is once again boosting this use. Canola and rapeseed-derived products can be used as additives to diesel fuel to reduce engine wear, as engine and hydraulic oils, and as lubricants in manufacturing processes. A high erucic acid rapeseed (HEAR) has been bred and is grown for various specialized end uses, including industrial lubricants, plastics, lacquers, and detergents. It represents relatively little of the total seeded area compared to canola – approximately 1% to 2% of total seeded area. While canola contains less than 2% erucic acid, the specialized high erucic acid varieties of rapeseed contain close to 50%.

The rapeseed industry in Canada started with demand for an industrial lubricant and recent research is once again boosting this use. Canola and rapeseed-derived products can be used as additives to diesel fuel to reduce engine wear, as engine and hydraulic oils, and as lubricants in manufacturing processes. A high erucic acid rapeseed (HEAR) has been bred and is grown for various specialized end uses, including industrial lubricants, plastics, lacquers, and detergents. It represents relatively little of the total seeded area compared to canola – approximately 1% to 2% of total seeded area. While canola contains less than 2% erucic acid, the specialized high erucic acid varieties of rapeseed contain close to 50%.

Since it was first developed, subsequent improvements have produced canola varieties more resistant to disease and weeds, with improved crop yield, quality and shorter maturity time. Researchers use traditional cross-breeding techniques and plant biotechnology—transferring a gene from one organism to another—to develop new canola varieties. Today canola researchers have a broad list of objectives and uses, including the production of bio-diesel.

Other research goals include increasing the average oil content in canola seed, as well as increasing the energy (calorie) content of canola meal to make it more valuable as poultry and swine feedstock. The industry is also working to develop canola varieties with larger seeds and thinner hulls, and to produce more stable oils that are less sensitive to oxidization (a chemical reaction affecting the oil quality).

In less than four decades a booming canola industry has emerged from experimental fields in the Prairies to gain significant ground in the world oilseed market. With continued research and development, it is easy to believe that this Canadian success story still has many chapters to go.

How to crush canola

Canola seeds contain on average 42.5% oil and it takes about 2.4 tonnes of canola seed (or about 1.6 hectares of canola) to produce one tonne or approximately 1,090 one-litre bottles of canola oil. The 3.6 million tonnes of canola seed crushed in 2006 produced approximately 1.6 million tonnes of oil and 2.1 million tonnes of canola meal.

Two main processes are involved in producing edible canola oil: primary processing, for crude canola oil, and secondary processing, for refined oil and canola meal.

Prior to processing, canola seeds must be stored at optimal temperatures and moisture levels with proper ventilation. Seeds are cleaned and foreign materials (“dockage”) such as weed seeds, other grains, straw and dirt are removed to prevent contamination.

Once cleaned, canola seeds are rolled through a mill and broken into flakes to reduce their size, and then cooked for 15 to 20 minutes. This “preconditioning” improves oil quality and helps maximize the amount of oil that can be recovered from the seeds. Seeds are put into presses and physically crushed, which extracts between 60% and 70% of the seed oil. The seeds (by now, no longer seeds but flattened into a “press cake”) are then treated with a solvent to extract the remaining oil. At the end of this process, 96% of the oil in the canola seeds has been recovered. The remaining meal, a valuable product in itself, is then heated to evaporate the remaining solvent.

Once cleaned, canola seeds are rolled through a mill and broken into flakes to reduce their size, and then cooked for 15 to 20 minutes. This “preconditioning” improves oil quality and helps maximize the amount of oil that can be recovered from the seeds. Seeds are put into presses and physically crushed, which extracts between 60% and 70% of the seed oil. The seeds (by now, no longer seeds but flattened into a “press cake”) are then treated with a solvent to extract the remaining oil. At the end of this process, 96% of the oil in the canola seeds has been recovered. The remaining meal, a valuable product in itself, is then heated to evaporate the remaining solvent.

The oil is distilled to remove any solvent and impurities are removed through settling, centrifugation, and filtration. The oil that remains after these purification steps is considered crude vegetable oil.

Further processing, called refining, improves the colour, odour and taste and makes it suitable for cooking. Additional processing steps can turn the oil into a variety of products, such as margarine or shortening.