Common menu bar links

That beet is sweet!

Archived Content

Information identified as archived is provided for reference, research or recordkeeping purposes. It is not subject to the Government of Canada Web Standards and has not been altered or updated since it was archived. Please "contact us" to request a format other than those available.

by Sarah Morrison, Statistics Canada

Did you know that you can get sugar from a beet? Although sugar cane is the crop most often associated with the production of refined sugar, approximately one-quarter of the world’s production actually comes from beets. We aren’t talking about your garden-variety beet, but instead sugar beets, a crop that is the result of the selective breeding of extra-sweet beets.

The sugar beet on the left has a different ancestry from the “ordinary” beet beside it. A beet used for cattle fodder in the Middle Ages is believed to have been the forerunner of the ‘White Silesian’, the original sugar beet developed in the 18th century. Today’s sugar beets descend from this humble forebear.

The sugar beet on the left has a different ancestry from the “ordinary” beet beside it. A beet used for cattle fodder in the Middle Ages is believed to have been the forerunner of the ‘White Silesian’, the original sugar beet developed in the 18th century. Today’s sugar beets descend from this humble forebear.

In 2006, 314 farms in Canada seeded 19,488 hectares with sugar beets according to the Census of Agriculture. Seeded area was up by 35% compared to the previous Census in 2001, a year in which farmers, faced with expected water shortages and low prices, shifted from sugar beets to other crops.

In 2006, Canadian farmers produced over 1.2 million tonnes of sugar beets, up nearly 80% from 2001. Most of this production took place in Alberta, where 963,000 tonnes of sugar beets were used to produce 124,000 tonnes of beet sugar. An additional 266,000 tonnes of beets were grown in Ontario and exported to Michigan for processing.

The birth of a new beet

While sugar was first extracted from a beet root in the mid-18th century, we may have Napoleon to really thank for this sugar source. During the Napoleonic wars at the turn of the 19th century, the Royal Navy was blockading French ports and France was cut off from its usual sugar supplies. Napoleon encouraged sugar beet production on a wide scale, setting up beet processing plants and schools specializing in sugar technology.

Early beet selection

Beets, biennial plants that grow leaves the first year and flower and produce seed the second, store energy from the first growing season in their roots as sugar, and then draw upon this energy in the second year to flower and produce seed. The beets are harvested after the first season for sugar production.

Beets, biennial plants that grow leaves the first year and flower and produce seed the second, store energy from the first growing season in their roots as sugar, and then draw upon this energy in the second year to flower and produce seed. The beets are harvested after the first season for sugar production.

German scientist Andreas Marggraf was the first to extract sugar from a beet root. Although he only extracted a small amount of sugar, his student, Franz Carl Achard, continued research on beet sugar and by 1802 the first sugar beet processing plants were established in what are now Germany and Russia.

During Andreas Marggraf’s early experiments, the sugar extracted was only about 1.6% of the beet’s total root weight. Today, however, average sugar content of an Alberta beet is about 19%, thanks to generations of farmers and researchers who selected only the sweetest beets as seed to propagate the line.

Early researchers found that the beets with the most sugar were also the heaviest. To select beets with the highest sugar content, one method was to throw the crop into a bath of saline water and use the beets that sank to the bottom to propagate the breed.

To this day, France is one of the world’s top sugar beet producers, and most of Europe still uses beets as the primary sugar source. Out of the world’s top 10 sugar beet-producing countries in 2006, eight were European (Table 1). Canada’s production of sugar beets is ranked 31st in the world.

Table 1

The world’s top 10 sugar beet-producing countries, by quantity, and Canada's production, 2006

The cane versus the beet…

Although the beet is popular in Europe, much of the rest of the world uses sugar cane as the raw material for refined sugar. (Refined sugar is available in a number of different forms, including granulated white sugar, liquid sugar, icing sugar and brown sugar.) While we don’t have the climate for sugar cane in Canada, Table 2 shows the countries growing the most sugar cane, and the quantity they produce.

Although the beet is popular in Europe, much of the rest of the world uses sugar cane as the raw material for refined sugar. (Refined sugar is available in a number of different forms, including granulated white sugar, liquid sugar, icing sugar and brown sugar.) While we don’t have the climate for sugar cane in Canada, Table 2 shows the countries growing the most sugar cane, and the quantity they produce.

Globally, production of sugar from sugar cane dwarfs that from sugar beets—cane sugar makes up about three-quarters of all raw sugar produced worldwide. But why do some regions prefer sugar cane and some prefer sugar beets as the source of their refined sugar?

It has nothing to do with taste. The sugar produced from both sugar beets and sugar cane is identical and is chemically known as sucrose. It does have something to do with geography though. Sugar cane is a tropical crop, so prior to the development of sugar beets, trade was necessary for northern countries wanting a sugar source. But as Napoleon saw, these trade routes could be disrupted. Many countries with a temperate climate saw sugar beets as an opportunity to develop their own domestic sugar industry.

Sugar cane, however, still has a price advantage. Although production costs for both beet sugar and cane sugar have been declining over the last 30 years, costs for cane sugar have been declining faster. Average beet sugar production costs worldwide are now significantly higher than those for cane sugar. The trade policies (such as tariff rate quotas) and subsidies to producers (such as price guarantees) that many countries use to protect their domestic industries have heavily influenced the world’s sugar market.

From beet to sugar and beyond: processing sugar beets

After sugar beets are harvested in the fall, they are shipped to receiving centres, where they are kept until the plant is ready to process them. At the factory, they are washed, then sliced into thin, noodle-like strips called cossettes.

After sugar beets are harvested in the fall, they are shipped to receiving centres, where they are kept until the plant is ready to process them. At the factory, they are washed, then sliced into thin, noodle-like strips called cossettes.

Making juice

To extract sugar from the beets, the cossettes are soaked in hot water. This produces a sugar-rich juice, which is heated, then mixed with a lime (calcium oxide) solution that reacts with many of the non-sugar impurities in the juice. Next, carbon dioxide is added, which reacts with the lime to form solid calcium carbonate which precipitates from the sugar solution carrying with it the impurities, which are then filtered out. When the purification process is complete, the juice is known as “thin juice.”

This “thin juice,” which contains less than 20% solids, is then concentrated by evaporating as much water as possible to produce “thick juice,” which contains about 70% solids. Thick juice can either be sent for further processing into granulated sugar immediately, or it can be stored for processing into granulated sugar at a later date.

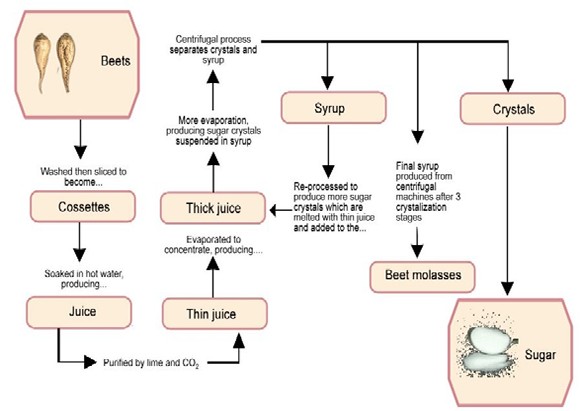

Thick juice is evaporated further in vacuum pans, producing sugar crystals suspended in syrup. This mixture is fed into a centrifugal machine, a large circular basket rotated at high speed to separate the crystals from the syrup. Then the crystals are washed and dried. The resulting pure sugar is stored until ready for packaging or for liquid sugar production. The syrup left after the initial crystallization process is put through the process twice more (Figure 1). Any remaining syrup is known as beet molasses, which is sold for yeast production or as a liquid animal feed supplement.

Figure 1

Processing sugar beets

Leftovers

Sugar beets have other useful byproducts. Remember those cossettes? When they began the extraction process, they were about 18% to 19% sugar but once finished, they contain less than 0.5% sugar and about 90% water. The exhausted cossettes are pressed in pulp presses to remove as much of the remaining water as possible. This water is returned to the sugar extraction process, since it still contains some sugar. Most of the pressed pulp is then dried and pelleted, and sold for animal feed. Pressed pulp can also be sold directly for livestock feed without drying. The sugar beet leaves and tops removed after harvesting may also be used as local livestock feed.

Sugar beets—saving lives?

In Saint John, New Brunswick, a product made from de-sugared beet molasses is used as a de-icing product on the Harbour Bridge. Sand and salt are no match for the extremely cold temperatures that combine with ocean vapour to make the bridge dangerously slippery in winter. The molasses-based product, however, has a lower melting point than road salt and, when used with it, enhances the effectiveness of the salt and reduces corrosiveness. In general, the de-icing product is effective to about -34 degrees Celsius.

The molasses de-icing product is also used in major Ontario cities such as Toronto and Mississauga, and is gaining popularity in the American Midwest and New England.

And then there’s corn…

While cane and beets are the main source of refined sugar, they are only part of the sweetening industry. Corn syrup has been with us for a long time and corn-based sweeteners are now playing an expanded role. High-fructose corn syrup, a product that had its manufacturing process patented by a Japanese scientist in 1971, is considered an excellent substitute for liquid sugar. (Fructose, commonly found in fruits, is the sweetest natural sugar, and while regular corn syrup is 100% glucose, high-fructose corn syrup is approximately half glucose and half fructose. It is similar in sweetness to sucrose [refined white sugar].)

While cane and beets are the main source of refined sugar, they are only part of the sweetening industry. Corn syrup has been with us for a long time and corn-based sweeteners are now playing an expanded role. High-fructose corn syrup, a product that had its manufacturing process patented by a Japanese scientist in 1971, is considered an excellent substitute for liquid sugar. (Fructose, commonly found in fruits, is the sweetest natural sugar, and while regular corn syrup is 100% glucose, high-fructose corn syrup is approximately half glucose and half fructose. It is similar in sweetness to sucrose [refined white sugar].)

As a major corn producer, the United States readily adopted the technology. Thanks to support of its domestic corn industry, high-fructose corn syrup has been cheap and, in the late 1980s, the product began to replace sugar in the soft drink and other food processing industries.

Changes in diets and consumer preferences as well as competition from newer sweetening products and low-calorie artificial sweeteners has hurt the traditional sugar industry. Per capita apparent consumption of refined sugar (sucrose) in Canada has declined from a high of 33.0 kilograms per year in 1973 to 22.3 kilograms in 2006.

Sugar beets in Canada

Sugar beet crops were initially attempted in Quebec during the latter part of the 19th century, while Ontario’s beet industry was established in 1902 and soon grew to be a significant agricultural industry during the course of World War I, the post-war boom and the Depression. A number of sugar beet processing plants were built, and between 1911 and 1951 producers reported increasing hectares planted with sugar beets in each successive census.

The crop’s area reached its peak in 1951, when the Census of Agriculture reported 38,716 hectares of the crop (Figure 2). However, with a few exceptions, the continuous decline in the world price of raw cane sugar, international trade and support policies and competition from other sweetening products have decreased the Canadian area planted to sugar beets. Current sugar beet area as reported in the last Census is about half of what it was at its peak.

Figure 2

Canadian sugar beet seeded area, census years, 1911 to 2006

Alberta: Canadian home of the sugar beet

Alberta has had the largest share of the country’s sugar beet area since 1951 according to Census of Agriculture data. Survey data between censuses, however, show some volatility in seeded area; for example, in 1985 no sugar beets were grown in the province when sugar beet growers and the processing plant were unable to agree on pricing. In 2006, Alberta had 81% (15,703 hectares) of the country’s sugar beet area, all of it in the Taber area. Farm cash receipts for sugar beets grown in Alberta were $38.2 million in 2006, up 19% from 2005.

Alberta has had the largest share of the country’s sugar beet area since 1951 according to Census of Agriculture data. Survey data between censuses, however, show some volatility in seeded area; for example, in 1985 no sugar beets were grown in the province when sugar beet growers and the processing plant were unable to agree on pricing. In 2006, Alberta had 81% (15,703 hectares) of the country’s sugar beet area, all of it in the Taber area. Farm cash receipts for sugar beets grown in Alberta were $38.2 million in 2006, up 19% from 2005.

Between 1956 and 1996, Manitoba’s sugar beet area was second only to Alberta’s. But when access to the United States, which had become the province’s principal market for refined beet sugar, was restricted in 1997 Manitoba’s only processing plant halted production.

Sugar beets return to Ontario

Ontario had over two-thirds of the Canadian sugar beet area from 1911 to 1931 according to the Census of Agriculture. Until a recent resurgence in southwestern Ontario, primarily in the area between Windsor and London, sugar beet production had almost completely stopped after the province’s last beet processing plant shut down in 1968.

Increased demand from the United States has led to the return of a crop that had not been significant in the province for decades. In 2006, 3,785 hectares were planted to sugar beets in Ontario, mostly for export to Michigan for processing. The United States, which uses tariffs on processed sugar imports to keep domestic sugar prices high, has both substantial sugar cane and sugar beet production (Tables 1 and 2). But because unprocessed sugar-beet imports are not restricted, Ontario growers are tapping into this export market.

A tale of two regions

Canadian sugar beets are now primarily a regional product, focused around the lone sugar-beet processing plant in Taber, Alberta and in Ontario near the Michigan processing plant . The map shows how Canada’s sugar beet industry is currently focused around the Taber processing plant, and compares the current situation to 1951, when the country had sugar-beet processing plants across the country.

. The map shows how Canada’s sugar beet industry is currently focused around the Taber processing plant, and compares the current situation to 1951, when the country had sugar-beet processing plants across the country.

Where Canada gets its sugar

Canada imports a large amount of sugar cane in a semi-processed state, known as “raw sugar”. It is transported in bulk by cargo ships and refined in Canada. For this reason, all of Canada’s sugar cane refineries are located near major ports—in Vancouver, Toronto, and Montréal. The Taber plant has survived in Canada because of its location far from the major ports.

In most parts of Canada, it is cheaper to buy imported “raw sugar” in the semi-processed state than to produce our own. Since Canada has minimal tariffs on sugar and the world price of sugar is so low, over 90% of our country’s refined sugar is now processed from sugar cane. In the inland Prairie region though, transportation costs to ship sugar in from the coast are high enough to allow the beet sugar industry to be competitive. Sugar refined in Taber is primarily sold to consumers and food processors in Alberta, Saskatchewan, and Manitoba, with small amounts occasionally sold in British Columbia, Ontario, and the United States.

Growing sugar beets

Alberta’s distance from ports has been a factor in the success of its sugar beet industry—but its climate hasn’t hurt either. Sugar beets are mostly grown in temperate climates where warm days and cool nights encourage the plants to store sucrose in their roots. Southern Alberta, thanks to the Rocky Mountains, has this ideal combination of warm summer days and cool nights and sugar beets grown in Alberta have a very high sugar concentration.

Alberta’s distance from ports has been a factor in the success of its sugar beet industry—but its climate hasn’t hurt either. Sugar beets are mostly grown in temperate climates where warm days and cool nights encourage the plants to store sucrose in their roots. Southern Alberta, thanks to the Rocky Mountains, has this ideal combination of warm summer days and cool nights and sugar beets grown in Alberta have a very high sugar concentration.

A typical Alberta sugar beet has a sugar content of about 19%, by weight, although this can vary between years, and by location and crop variety. In Alberta, average yields are approximately 50 tonnes per hectare, which produce 6 tonnes of sugar on average. While sugar cane has a lower sugar content by weight (10%), average yields are higher, with 1 hectare producing about 100 tonnes of sugar cane, or 5 to 10 tonnes of raw sugar.

Although sugar beets are normally biennial (meaning they have a two-year life cycle), the Canadian winter is generally too cold for them to survive, so in this country they are treated as an annual crop. In Canada, sugar beets are seeded from mid-April to mid-May and harvested from September to early November.

A water-sensitive crop

Sugar beets are very sensitive to moisture levels and irrigation is an important factor in growing them. This characteristic was what made them attractive to the companies introducing irrigation to Alberta at the beginning of the 20th century who were looking for a crop that would support the project’s cost.

This same characteristic contributed to the demise of sugar beets in Manitoba, where the dependence on rainfall made yields less reliable. In 1996, the last year that Manitoba reported sugar beet production, the average yield of sugar beets in the province was 36 tonnes per hectare, low compared to Alberta where average yield was 50 tonnes per hectare. Although restricted access to the United States was the main reason behind Manitoba’s plant closure, yield comparisons show Alberta’s advantage—partly due to irrigation—in crop production. However, Albertan sugar beet farmers have been hurt by drought and water shortages in recent years.

Too much water can also be a problem, leading to beets with reduced sugar content. Since farmers are paid based on the sugar levels in their beets you can be sure they are careful not to overwater.

Crop rotation keeps pests at bay

Farmers growing sugar beets generally practise crop rotation, meaning they vary the crop grown on a section of land each year in order to minimize pests and disease. In Alberta, crop rotation for sugar beets is mandatory, and sugar beets are planted only once every four years, typically rotated with cereal crops, peas, dry beans, potatoes as well as sweet and forage corn.

Although sugar beets are susceptible to pests such as the sugar beet nematode, such long crop rotations mean that the pests cannot survive between planting cycles. In other sugar-beet growing areas without the land to allow for such long rotations, fields have to be fumigated. Because of the availability of land in Alberta, producers are not so restricted by land area and they can add this cost-saving to their list of beet-growing advantages.

The future of sugar beets

Although the area planted to sugar beets has been declining, there are signs that there is still a future in sugar beet production in Canada. In 1998, the Taber processing plant invested in upgrades that increased its capacity by 50%, and in both Alberta and Ontario, scientists continue to improve crop production techniques.

Although the area planted to sugar beets has been declining, there are signs that there is still a future in sugar beet production in Canada. In 1998, the Taber processing plant invested in upgrades that increased its capacity by 50%, and in both Alberta and Ontario, scientists continue to improve crop production techniques.

High energy prices have also led to an increased demand for ethanol, which can be produced from sugar cane. Brazil, the world’s largest sugar exporter, produced 16.9 billion litres of ethanol in 2006, diversification that has contributed to increased sugar prices. Ethanol can also be made from sugar beets, and several Canadian provinces, such as Quebec and Prince Edward Island, are looking into the economics of converting the crop to fuel.

In agriculture, as in real estate, location is key

The example of the sugar beet shows how important location is in agriculture. It can mean growing a crop in a well-suited climate, where it has ideal soil, rainfall (or irrigation), and sun. It can also mean growing a crop close to markets and avoiding high transportation costs. If costs become too high or lower-cost substitutes are readily available, history has shown that a processing plant will shut down in a region and the sugar beet crop will disappear. Although sugar beets can’t compete with imported raw sugar cane near Canada’s ports, they have been able to profitably respond to local market needs in land-locked Alberta.